large drum horizontal grinder for whole tree/stump/pallet

The drum horizontal grinder is also called as multi-functional wood crusher. This machine adopts chain plate type intelligent feeding, which can automatically adjust the feeding speed according to the load of the main motor. It can make the machine run at full load to avoid no-load operation, make the feeding smoother, and greatly improve the production capacity. With the help of a fully automatic hydraulic lifting system, the height of the inlet can be raised to 1000mm.

The drum horizontal grinder mainly relies on impact energy to complete the wood crushing operation. When drum horizontal grinder is working, the motor drives the rotor to rotate at a high speed, and the wood enters into the cavity of the drum horizontal grinder evenly. The rotating hammer head rushes to the baffle plate and the sieve bar in the frame. In the lower part of the rotor, there is a sieve plate, and the particle size smaller than the sieve hole size in the crushed wood is discharged through the sieve plate, and the wood larger than the sieve hole size is blocked on the sieve plate. Continue to be hit and ground by the hammer, that is to say, the fineness of crushing can be adjusted according to the needs of users.

Due to its reasonable design, compact structure, safety, durability and high production efficiency, the drum horizontal grinder has received lots of positive feedback after being popularized and used. It has low noise, simple structure, compact layout, low price, stable work, low energy consumption and high output. Quality of the crushed product is excellent, and the processing cost is low. Crushed wood is widely used in edible fungi production, biomass power plants, biomass pellets, incense production, paper production and other industries.

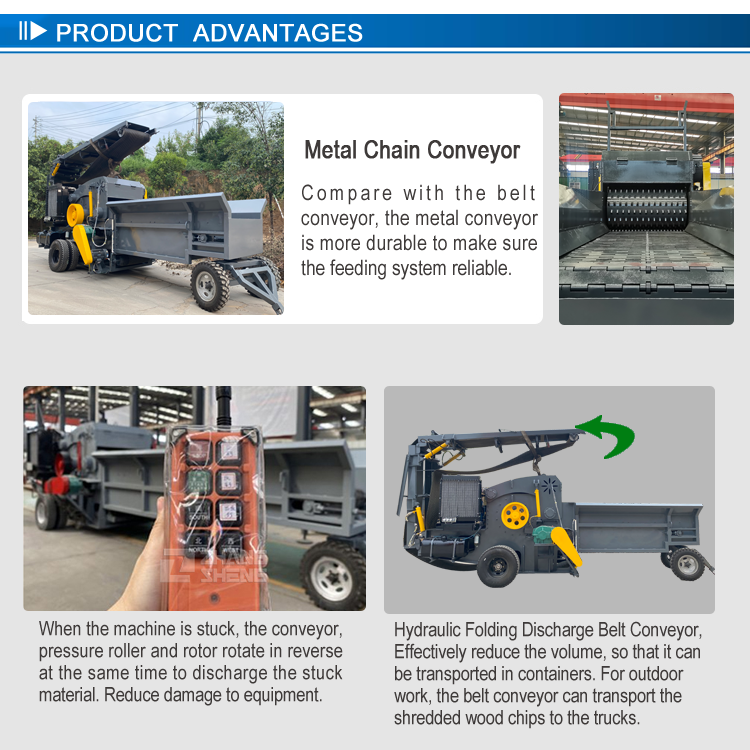

1. Meshing blade is used to completely crush materials;

Special blade shall be selected, and the blade hardness shall not be lower than HRC55;

2. Strong structure and densely distributed stiffening plates ensure the strong and solid of the box;

3. Automatic button, remote control, safe and convenient;

4. Discharge conveyor belt and iron removal device can be equipped.

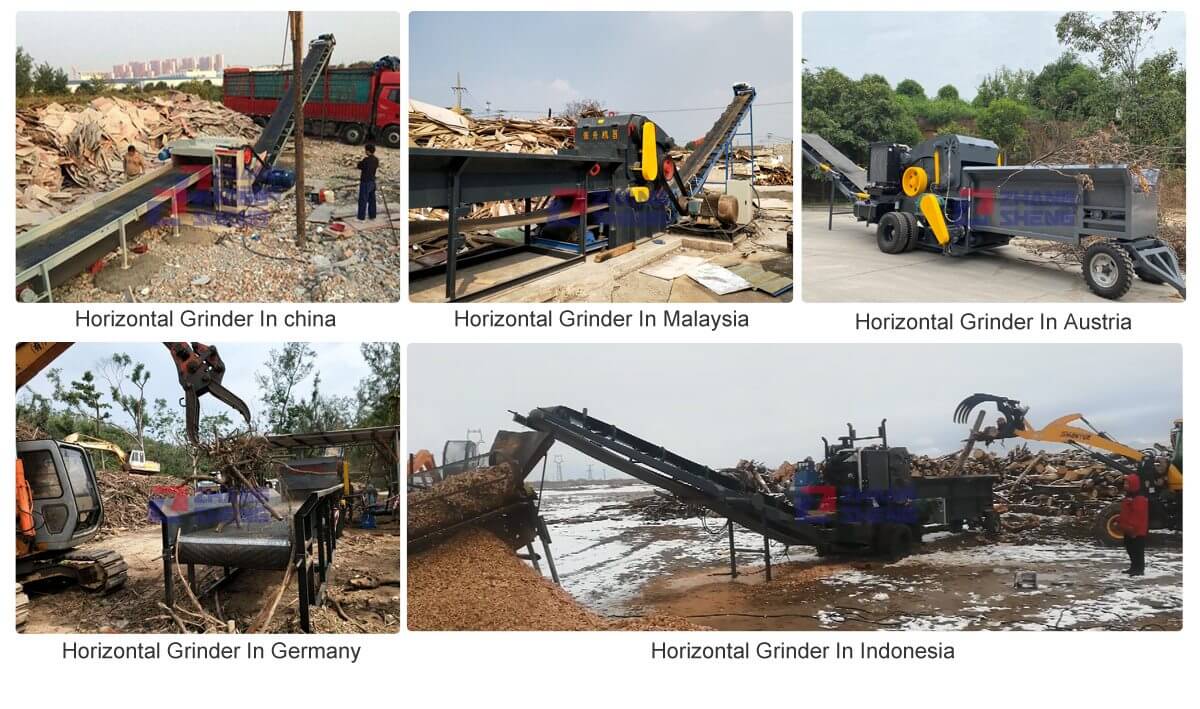

The strength of a business is defined with what it can provide for its customers. Here at Zhangsheng Machinery, we aim to be the machine shop that you can rely on. We take pride with the capabilities we have and the excellent services we have to offer for each customer. We are dedicated to ensuring that you have the best experience in our shop.

Expert Precision Machining

Whether it’s machining large complex parts from exotic alloys or simple production runs – we can handle the project for you with precision. We have the capabilities to handle large and heavy parts.

Rest assured that when you entrust a project to us, we will not just accommodate the work we will see that it’s completed with confidence and accuracy throughout all of the process steps.

Fully Equipped Machine Shop/Facilities

Our machine shop is fully equipped with the personnel, software and machines to deliver the best result for you. Our milling and turning machines have large size capacity. With us, no project is too small or too large. Our leading edge facility has the room to welcome your projects.

Personalized Services

Be it on production runs or single piece – we will be communicating and delivering an excellent service to you. We offer manufacturing engineering in along with our value-add machine shop.

Our goal is to develop strong relationships with our customers. To do that we understand that on-time delivery, quality and communication are all key. Understanding your business and your needs is key to long term customer success.

Quality Work

Quality at Zhangsheng Machinery encompases all facets of the business; from the pre-machining process to making sure the parts are to print and order requirements, from quote turnaround response to ontime delivery. Quality is a repeatable process and is visible in every single project that we do.

|

Model

|

Engine Power (hp)

|

Feed Port Diameter (mm)

|

Spindle Speed (r/min)

|

Motor Power (kw)

|

Output Capacity (kg/h)

|

|

ZS800

|

200

|

800×1000

|

900

|

75/90

|

8000-10000

|

|

ZS1000

|

260

|

1000×1000

|

800

|

90/110

|

10000-12000

|

|

ZS1300

|

320

|

1300×1000

|

800

|

132/160

|

12000-15000

|

|

ZS1400

|

400

|

1400×1000

|

800

|

185/200

|

15000-20000

|

|

ZS1600

|

500

|

1600×1000

|

800

|

220/250

|

25000-35000

|

|

ZS1800

|

700

|

1800×1000

|

800

|

315

|

40000-50000

|

1. Are you a manufacturer or trading company?

We are manufacturer with 20 years' experience.

2. How long is your leading time?

7-10 days for the stock, 15-30 days for the mass production.

3. What is your payment method?

30% deposit in T/T advance, 70% balance before shipment. For regular customers, more flexible payment ways are negotiable

4. How long is the warranty? Does your company supply the spare parts?

One year warranty for main machine, wearing parts will be provided at cost price

5. How can I choose the suitable machine?

Please contact our sales consultants and tell them your requirement such as natural material size, finished product size, capacity requirement, etc. Our sales consultant will advise suitable machine for you.

6. Can we visit your factory?

Sure, you are warmly welcome to visit.